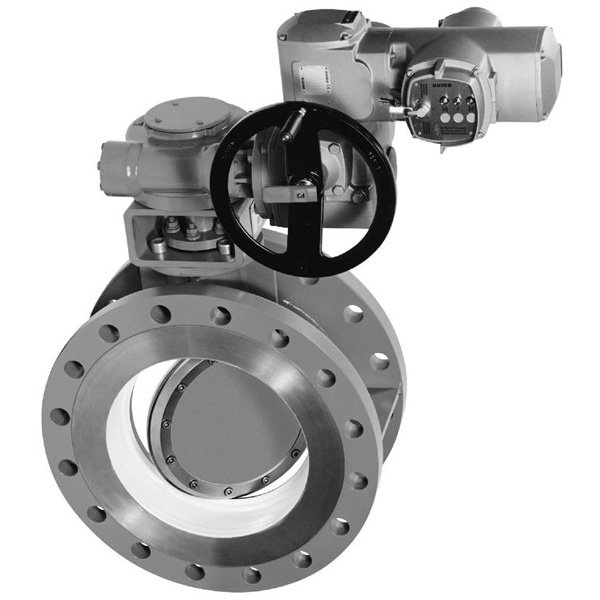

Features:

1.Wtih eccentric structure, the body sealing faces are elastic metal rings and multi-layer sealing face to make the disc

2.Sealing : metal to metal or soft sealing.

3.Designing standard : API 609, JIS B2064, EN593, GB/T12238

4.Flange standard: ANSI B16.5, JIS B2212, EN1092.1, GB/T 9113.1

5.Face to face according to ANSI B16.10, JIS B2002, EN558.1, GB/T12221

Material List:

| Part Name | Material |

| Body | WCB, WC6, WC9, CF8, CF8M, CF3, CF3M, C95800, 904L |

| Disc | WCB, WC6, WC9, CF8, CF8M, CF3, CF3M, C95800, 904L |

| Seal ring | SS+Graphite, PTFE, RPTFE, EPDM, NBR |

| Stem | 2Cr13, F304, F316, F304L, F316L, 17-4PH, UNS N05500, C6300 |

| Pakcing | FLEXIBLE GRAPHITE |

Dimension List:

| Dimensions, PN10, PN16, PN25, JIS 10K, JIS 20K | ||||||||||||

| DN(mm) | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 |

| L(Short) | 108 | 112 | 114 | 127 | 140 | 140 | 152 | 165 | 178 | 190 | 216 | 222 |

| L(Long) | 150 | 170 | 180 | 190 | 200 | 210 | 230 | 250 | 270 | 290 | 310 | 330 |

| Dimensions, PN10, PN16, PN25, JIS 10K, JIS 20K | |||||||||||

| DN(mm) | 500 | 600 | 700 | 800 | 900 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 |

| L(Short) | 229 | 267 | 292 | 318 | 330 | 410 | 470 | 530 | 600 | 670 | 760 |

| L(Long) | 350 | 390 | 430 | 470 | 510 | 550 | 630 | 710 | 790 | 870 | 950 |

| Dimensions, PN40 | |||||||||||||

| DN(mm) | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 |

| L(Short) | 108 | 112 | 114 | 127 | 140 | 140 | 152 | 165 | 178 | 190 | 216 | 222 | 229 |

| L(Long) | 150 | 170 | 180 | 190 | 200 | 210 | 230 | 250 | 270 | 290 | 310 | 330 | 350 |

| Dimensions, PN63 | |||||||||||

| DN(mm) | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 |

| L | 150 | 170 | 180 | 190 | 200 | 210 | 230 | 280 | 270 | 290 | 310 |

| Dimensions, Class 150, Class 300 | |||||||||

| DN(mm) | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

| L | 108 | 112 | 114 | 127 | 140 | 140 | 152 | 165 | 178 |

| Dimensions, Class 150, Class 300 | |||||||||

| DN(mm) | 350 | 400 | 450 | 500 | 600 | 700 | 800 | 900 | 1000 |

| L | 190 | 216 | 222 | 229 | 267 | 292 | 319 | 330 | 410 |

| Dimensions, Class 600 | |||||||||

| DN(mm) | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

| L | 150 | 170 | 180 | 190 | 200 | 210 | 230 | 270 | 270 |

| Dimensions, Class 600 | |||||||||

| DN(mm) | 350 | 400 | 450 | 500 | 600 | 700 | 800 | 900 | 1000 |

| L | 290 | 310 | 330 | 350 | 390 | 430 | 470 | 510 | 550 |

Main Technical Parameter:

| Nominal diameter | DN | 50-2000 | ||||||

| Nominal pressure | PN/CLASS | 0.6 | 1.0 | 1.6 | 2.5 | 4.0 | 150LB | 300LB |

| Test pressure | Shell test | 0.9 | 1.5 | 2.4 | 3.75 | 6.0 | 3.0 | 5.0 |

| Seal test | 0.66 | 1.1 | 1.76 | 2.75 | 4.4 | 2.2 | 7.5 | |

| Air test | 0.6 | |||||||

| Applicable medium | water,steam,oil products,corrosive acid,etc. | |||||||

| Applicable temperature | -29~650°C | |||||||

| Operator | lever, handle, worm gear, electric, pneumatic, hydraulic | |||||||

Applications:

Foodstuff, pharmacy, petrochemical industry and power plant.