Main Technical Parameters:

Size: from DN40 to DN600

Nonimal Pressure: PN10, PN16, PN25, CL125, CL150

Face to face dimension: DIN3352 F4/F5, EN558-1, ASME B16.10

Flanged drilling : EN 1092-2, ANSI B16.1/16.5/16.42, ISO 7005

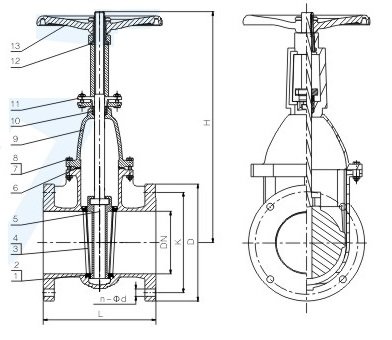

Material List:

| No. | Part Name | Material |

| 1 | Body | Cast Iron/Ductile Iron |

| 2 | Seal Face | Brass/Bronze/SS304 |

| 3 | Disc | Cast Iron/Ductile Iron |

| 4 | Sealing Face | Brass/Bronze/SS304 |

| 5 | Stem | SS410/SS304 |

| 6 | Gasket | EPDM/NBR/Graphite |

| 7 | Bolt | C.S./S.S. |

| 8 | Nut | C.S./S.S. |

| 9 | Bonnet | Cast Iron/Ductile Iron |

| 10 | Packing | Graphite/PTFE |

| 11 | Packing Gland | Cast Iron/Ductile Iron |

| 12 | Stem Nut | Ductile Iron/Brass |

| 13 | Handwheel | Ductile Iron |

Dimensions:

| DN | Inch | GB/T12221 | DIN 3352 | JIS B2002 | ANSI B16.10 | EN1092-2 | ANSI B16.1 | ||||

| BS5163 | F4/F5 | PN10/16 | CL125/150 | ||||||||

| L | D | K | n-φd | D | K | n-φd | |||||

| 40 | 1.1/2 | 165 | 140/240 | 165 | 165 | 150 | 110 | 4-19 | 127 | 98.5 | 4-15 |

| 50 | 2 | 178 | 150/250 | 180 | 178 | 165 | 125 | 4-19 | 152 | 120.5 | 4-19 |

| 65 | 2.1/2 | 190 | 170/270 | 190 | 190 | 185 | 145 | 4-19 | 178 | 139.5 | 4-19 |

| 80 | 3 | 203 | 180/280 | 200 | 203 | 200 | 160 | 8-19 | 190 | 152.5 | 4-19 |

| 100 | 4 | 229 | 190/300 | 230 | 229 | 220 | 180 | 8-19 | 229 | 190.5 | 8-19 |

| 125 | 5 | 254 | 200/325 | 250 | 254 | 250 | 210 | 8-19 | 254 | 216 | 8-22 |

| 150 | 6 | 267 | 210/350 | 270 | 267 | 285 | 240 | 8-23 | 279 | 241.5 | 8-22 |

| 200 | 8 | 292 | 230/400 | 290 | 292 | 340 | 295 | 8-23/12-23 | 343 | 298.5 | 12-22 |

| 250 | 10 | 330 | 250/450 | 330 | 330 | 395/405 | 350/355 | 12-23/12-27 | 406 | 362 | 12-25 |

| 300 | 12 | 356 | 270/500 | 350 | 356 | 445/460 | 400/410 | 12-23/12-27 | 483 | 432 | 12-25 |

| 350 | 14 | 381 | 290/550 | 381 | 381 | 505/520 | 460/470 | 16-23/16-31 | 533 | 476.5 | 12-29 |

| 400 | 16 | 406 | 310/600 | 406 | 406 | 565/580 | 515/525 | 16-28/16-31 | 597 | 539.5 | 16-29 |

| 450 | 18 | 432 | 330/650 | 432 | 432 | 615/640 | 565/585 | 20-28/20-31 | 635 | 578 | 16-32 |

| 500 | 20 | 457 | 350/700 | 457 | 457 | 670/715 | 620/650 | 20-28/20-34 | 699 | 635 | 20-32 |

| 600 | 24 | 508 | 390/800 | 508 | 780/840 | 725/770 | 20-31/20-37 | 813 | 756 | 20-32 | |

| 700 | 28 | 610 | 430/900 | 610 | 895/910 | 840 | 24-31/24-37 | ||||

| 800 | 32 | 660 | 470/1000 | 660 | 1015/1025 | 950 | 24-34/24-41 | ||||

| 900 | 36 | 711 | 510/1100 | 711 | 1115/1125 | 1050 | 28-34/28-41 | ||||

| 1000 | 40 | 813 | 550/1200 | 813 | 1230/1255 | 1160/1170 | 28-37/28-44 | ||||

Applications:

Irrigation, fire-fighting services, sewage treatment and pumping