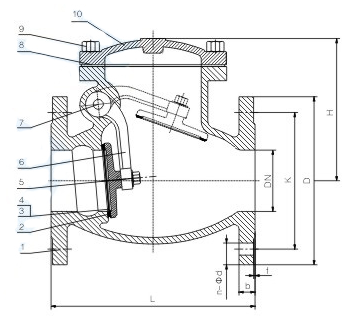

Bolted bonnet with eyebolt on bonnet

Swing disc and metal sealing

Design according to BS 5153, MSS SP-71

Flange connection standard: GB/T 9113, EN1092-2 PN10/PN16, ANSI B16.10 125LB/150LB

Pressure test: EN 12266-1

Size range : 2″ to 24″, DN50 to DN600

Pressure range : PN10, PN16, CL125/150

Material List:

| Part Name | Material |

| Body | Ductile Iron |

| Bonnet | Ductile Iron |

| Disc | Ductile Iron |

| Gasket | EPDM |

| Bolts | AISI 1045 |

Dimension List:

|

DN |

Outline(mm) | EN1092-2 | ANSI B16.1/16.42 | ||||||

| BS5153 | ASME B16.10 | DIN F6 | PN10/16 | CL125/150 | |||||

| L | D | K | n-φd | D | K | n-φd | |||

| 40 | 165 | 165 | 180 | 150 | 110 | 4-19 | 127 | 98.5 | 4-15 |

| 50 | 203 | 203 | 200 | 165 | 125 | 4-19 | 152 | 120.5 | 4-19 |

| 65 | 216 | 216 | 240 | 185 | 145 | 4-19 | 178 | 139.5 | 4-19 |

| 80 | 241 | 241 | 260 | 200 | 160 | 8-19 | 190 | 152.5 | 4-19 |

| 100 | 292 | 292 | 300 | 220 | 180 | 8-19 | 229 | 190.5 | 8-19 |

| 125 | 330 | 330 | 350 | 250 | 210 | 8-19 | 254 | 216 | 8-22 |

| 150 | 356 | 356 | 400 | 285 | 240 | 8-23 | 279 | 241.5 | 8-22 |

| 200 | 495 | 495 | 500 | 340 | 295 | 8-23/12-23 | 343 | 298.5 | 12-22 |

| 250 | 622 | 622 | 600 | 395/405 | 350/355 | 12-23/12-27 | 406 | 362 | 12-25 |

| 300 | 698 | 698 | 700 | 445/460 | 400/410 | 12-23/12-27 | 483 | 432 | 12-25 |

| 350 | 787 | 787 | 800 | 505/520 | 460/470 | 16-23/16-31 | 530 | 476.5 | 12-29 |

| 400 | 914 | 914 | 900 | 565/580 | 515/525 | 16-28/16-31 | 595 | 539.5 | 16-29 |

| 450 | 965 | 965 | 1000 | 615/640 | 565/585 | 20-26/20-30 | 635 | 578 | 16-32 |

| 500 | 1067 | 1067 | 1100 | 670/705 | 620/650 | 20-25/20-34 | 700 | 635 | 20-32 |

| 600 | 1219 | 1219 | 1300 | 780/840 | 725/770 | 20-30/20-41 | 815 | 749.3 | 20-35 |